sauce filling machine curry paste automatically

- Description

- Additional information

- Inquiry

Description

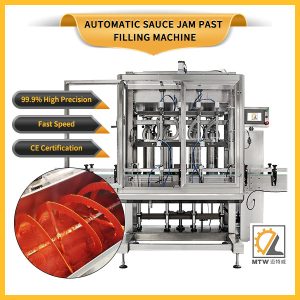

Sauce filling machine curry paste automatically

This sauce filling machine curry paste automatically adopts piston pump and rotary valve, suitable for filling all kinds of thick & sticky material:

In food industry like honey, sauce, jam, marmalade, tomato paste, ketchup, chocolate paste, luncheon meat etc.

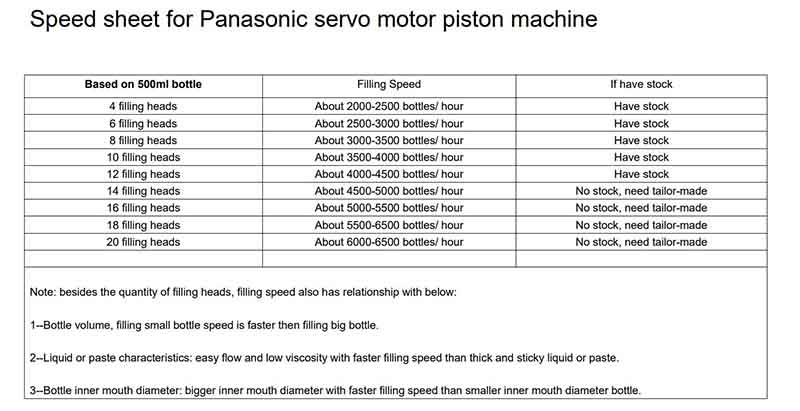

It can made in 1/2/4/6/8/10/12 nozzles as different speed requirments

Below is the specification of the sauce filling machine curry paste automatically

This sauce filling machine curry paste automatically has many advantages and features

–Thickness 3.5mm

We use SUS316L & SUS304 with thickness 3.5mm

–Hopper with heat and mixture with liquid level control system

There is is liquid level control system, which worked together with transfer pump to transfer

liquid from storage tank on ground to filling machine hopper on the top.

When hopper is near full, the transfer pump stop working; when hopper is near empty,

the feeding pump start transfer liquid into hopper again.

–High quality piston pump

we could choose piston pump according to your bottle liter , for example 100-1000ml , you could choose 1L piston pump , 500ml-5000ml choose 5L piston pump 250ml-2.5L choose 2.5L piston pump

–316L food grade touching part

Besides piston pump, the liquid contacted parts, are all SUS316L, like valve, tube, filling heads, screw and nut

The sealing ring inside piston pump we use is Polytetrafluoroethylene, good sealing effect and long use life.

food grade hose can bear from -60degree to 200 degree

–Adjustable and Customizable filling nozzles with anti-drop function

We have different kinds filling heads to suit different liquid and paste. For foaming liquid, we use diving filling heads.

The filling nozzles are customizable and adjustable to fit different bottles

–We use international brand accessories

we use panasonic servo motor , Taiwan or Germany Airtac ,Schneider France relay ,JSCC Germany Inverter and so on

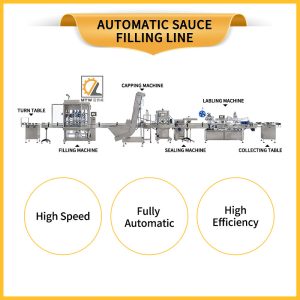

–Professional conveyor belt suggestions

we have two kinds of conveyor belt

SUS304 conveyor with thickness 3mm ;Plastic conveyor with thickness 4mm ;we will suggest a better one according to different products or containers

We can make both straight conveyor & twist conveyor as your layout

Packing way

1. The machine is wrapped with PE film to prevent the parts from loosening due to bumps

2. Fix it on the tray with nylon tape to prevent the machine from shaking and bumping

3. The machine will be packed in synthetic plywood to prevent extrusion during transportation

Warrenty and after sale service

1/ When shipping, we will send enough accessories to ensure you have enough accessories to us , which you can use 1-2year

2/ 12months of free maintenance or replacement for touch screen, frequency inverter, PLC controller, photoelectric sensor;

3/ 7*24-hour online after-sales service, which can provide to answer questions about the operation of machine and take video to show our customer how to solve the problems;

4/ Our factory has a team of engineers for worldwide after-sales, they have been responsible for installation and debugging of machine and training of operators;they can go abroad to train your customers and we also offer online training and video guard as well . once you received the machine . you , me your technologists and our technologists will add in a group and then we discuss the issues when you met in the production

5/can offer Operation manual

if you are interested in this sauce filling machine curry paste automatically ,please contact MTW filling machine

contact

Zora wang

Email:[email protected]

Whatsapp:008615822179405

Follow our MTW Filling Machine Youtube

Additional information

| Name | Automatic sauce filling machine for honey scrupt filling |

|---|---|

| Material | SUS304 and SUS316L |

| Filling heads | 4/6/8/10/12nozzles |

| Filling range | 10-100ml/ 30-300ml/ 50-500ml/ 100-1000ml/ 250-2500mml/ 300-3000ml/ 500-5000ml |

| Filling speed (bottles/ hour & based on 500ml bottle) | 2000-2500BPH/2500-3000BPH/3000-3500BPH/3500-4000BPH/4000-4500BPH |

| Filling precision | 0.2%-0.5% |

| Power | 220/380V 50/60Hz 1.5Kw (Can be tailor made to suit different countries) |

| Air pressure | 0.4-0.6Mpa |

| Machine size (L*W*Hmm) | 2000*900*2200mm/2400*900*2200mm/2800*900*2200mm/3200*900*2200mm/3500*900*2200mm |

| Weight | 450Kg/500Kg/550Kg/600Kg/650Kg |