automatic liquid soap filling machine

- Description

- Inquiry

Description

The automatic liquid soap filling machine is the latest design of our company, which has been recognized and affirmed by many domestic and foreign enterprises in the filling production. The overall performance of the product has reached the international advanced level, and some performances exceed similar foreign products. This machine adopts frequency conversion motor, PLC and touch screen control system. The whole machine is easy to operate, maintain and adjust. All liquid touching parts are made of food grade 316 stainless steel. It is controlled by the original famous brand electric and gas components, and the operation is stable. Single cylinder and single control are adopted, and each filling cylinder is equipped with a metering fine-tuning device to ensure the consistency of the product accuracy of each bottle and further increase the filling volume.

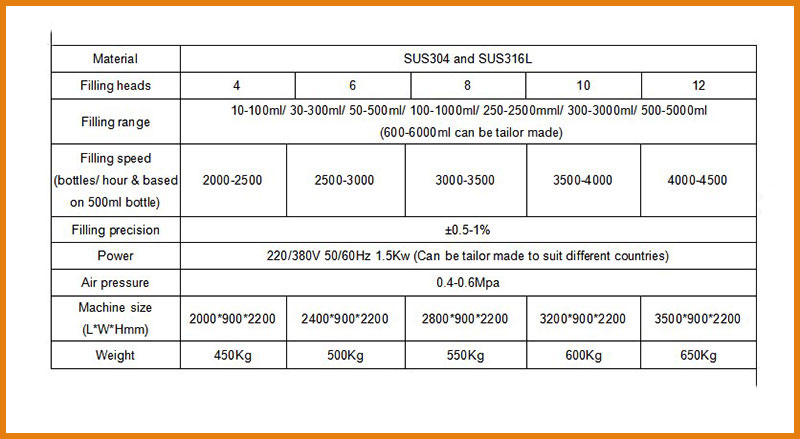

Below is the parameter of the automatic liquid soap filling machine

This automatic liquid soap filling machine is suitable for filling containers of different specifications, and the specifications can be switched within a few minutes.

The filling cycle is short and the production capacity is strong.

No need to add spare parts to change filling specifications, just adjust

Users can choose the number of filling heads according to their own production capacity.

The touch-operated color screen can display the production status, operating procedures, filling methods, etc. The screen is intuitive, easy to operate and easy to maintain.

Each filling head is equipped with a bottle clamping device to ensure accurate filling alignment.

Features:

The automatic liquid soap filling machine is durable and the failure rate is very low;

Servo piston drive, high precision 99.9%

All parts in contact with the material are made of 316 stainless steel

Variable speed filling (servo type): During the filling process, when the target filling volume is approaching, slow filling can be achieved through variable speed to prevent liquid from overflowing the bottle mouth.

Easy adjustment (servo type): to change the filling specification, you only need to change the parameters on the touch screen, and all the filling heads are replaced at one time, and you only need to adjust the fine-tuning dosage on the touch screen.

Functions can be customized according to customer requirements: heating, stirring, submerged filling, anti-pull filling, large particle filling head, high viscosity material filling, etc.

If you are interested in the automatic liquid soap filling machine

Please contact MTW filling machine Zora

Email:[email protected]

whatsapp:008615822179405

Youtube :MTW Filling Machine