peanut butter filling machine

- Description

- Inquiry

Description

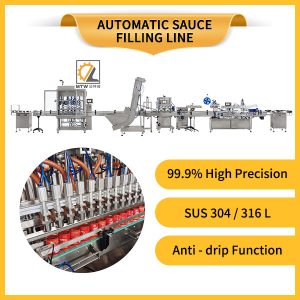

Automatic peanut butter filling machine

The Automatic peanut butter filling machine is made of food grade 316L stainless steel in contact with materials, fully in line with GMP standards. The peanut butter filling machine is connected by quick union, which is easy to remove and wash. The filling volume and filling speed can be adjusted. The bottles of different specifications and shapes can be replaced without changing parts, which is easy to adjust. In addition, the filling head of the peanut butter filling machine is equipped with a drip proof device, and there is no wiredrawing or drip during filling. Bottle filling, no bottle filling. The peanut butter filling machine is equipped with a counting function, which can accurately display the current output and the previous shift output, and is equipped with an automatic feeding control interface to achieve automatic control of the feeding. The automatic peanut butter filling machine is stable and accurate, and is an ideal mechanical and electrical integration product at present

Besides the single head peanut butter filling machine , we can also produce double heads lobe pump filling machine , 4heads rotor pump filling machine depending on your requirments

Automatic peanut butter filling machine Feathers

1/ There is a certain clearance between rotors, no friction coefficient and long service life.

2/Simple assembly and disassembly, convenient maintenance and cleaning, and few vulnerable parts

3/Energy saving, stable transmission, low failure rate, reliable sealing and low noise.

4/After using special materials, it can transport sludge, sewage and other media containing solid particles

5/Conveyable medium viscosity ≤ 500000 cp

6/After the frequency converter is configured, the flow can be adjusted at will and can be used as a general metering pump

7/Applicable temperature: – 50 ℃ – 250 ℃

8/The drive gear (outer rotor) with internal teeth drives the inner rotor to rotate in the same direction in the fully enclosed pump body. The crescent plate of the pump body and the front cover separates the suction inlet from the discharge outlet. When rotating, a negative pressure is formed at the suction inlet, and the liquid is sucked in. The rotor brings the liquid to the discharge outlet, and the pump body is discharged under pressure, thus completing the liquid transmission

If you are interested in the automatic peanut butter filling machine , contact MTW filling machine

Zora wang

whatsapp:008615822179405

Email:[email protected]

Youtube :Youtube :MTW Filling Machine